Filtering Flat Line Machines

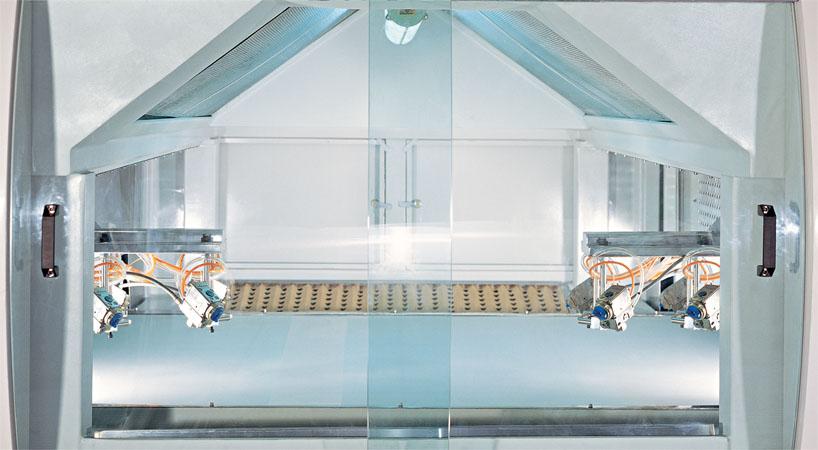

Flat line spray finishing machines are indispensable in high-volume manufacturing for applying uniform coatings to substrates like metal panels, wood composites, or automotive components. However, particulate contamination remains a pervasive threat to finish quality. Implementing robust filtration protocols directly impacts film integrity and operational efficiency.

Optimizing filtration efficiency for flat line finishing systems necessitates precise dimensional compatibility between exhaust filters and frames. Standard solutions often involve filter modifications: operators must either physically cut commercially available filters or commission custom-manufactured units. This dimensional calibration constitutes a critical preparatory phase for maximizing overspray particulate capture efficiency.

Filter Media Selection

Filter media selection follows application-specific thermodynamic and fluid dynamic principles:

– Polyester: Optimal for moderate-temperature environments (<120°C) due to thermoplastic stability

– Fiberglass: Required for high-temperature operations (>230°C) leveraging inorganic fiber resilience

– Expanded paper: Provides electrostatic enhancement for submicron particulate agglomeration

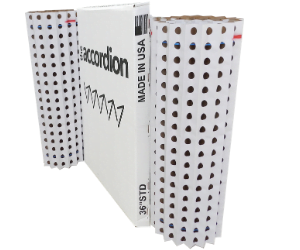

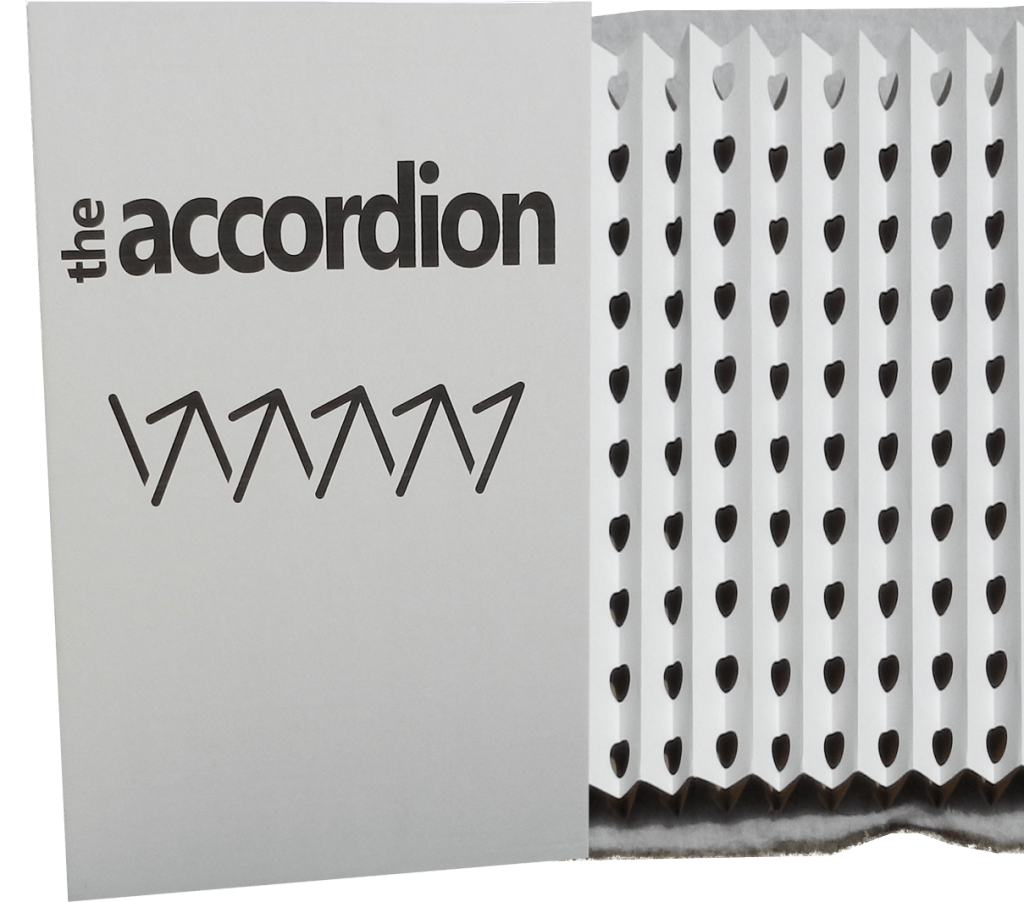

– Accordion paperboard: Increase surface area by 300-400% via Bernoulli’s principle, reducing velocity-driven particle bounce

Selection parameters must align with Stokes’ law calculations for particle settling velocities and the Reynolds number of airflow patterns. Capture efficiency (η) follows the relationship η ∝ (1 – e k·A/v), where A = effective filtration area, v = face velocity, and k = media-specific capture coefficient. Thus, media choice directly governs the exponential decay of particulate transmission.

Source: *Aerosol Technology* (Hinds, 1999), Chapters 9 & 12; *Filtration of Particles from Gases* (Davies, 1973).

Ignoring filtration transforms spray systems into defect generators. Strategic investment in filtration cuts waste, elevates quality consistency, and extends hardware service life.

-

Compare to Binks, Andreae, Chemco and Compleat accordion style, single stage filters. The Accordion is the better baffle for overspray collection. 10+ boxes ship free!

Price range: $56.00 through $65.00

Select options This product has multiple variants. The options may be chosen on the product page -

Compare Binks, Andreae, Chemco and Compleat accordion style high efficiency filters to The Accordion, the only American made accordion overspray collector. 10+ boxes ship free!

Price range: $61.00 through $69.00

Select options This product has multiple variants. The options may be chosen on the product page -

The SF28 Series Premium Fiberglass Filter is engineered with a distinctive 28-gram fiberglass, ensuring optimal airflow and superior paint retention. It adheres to EPA 6H regulations, providing exceptional performance.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $166.68 through $1,017.55

Select options This product has multiple variants. The options may be chosen on the product page -

The PEY Series Polyester Paint Arrestor is a high efficiency, 2″ dry polyester media made for medium to heavy duty filtration applications where performance and the removal of a wide range of particles is the priority.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $273.99 through $497.75

Select options This product has multiple variants. The options may be chosen on the product page -

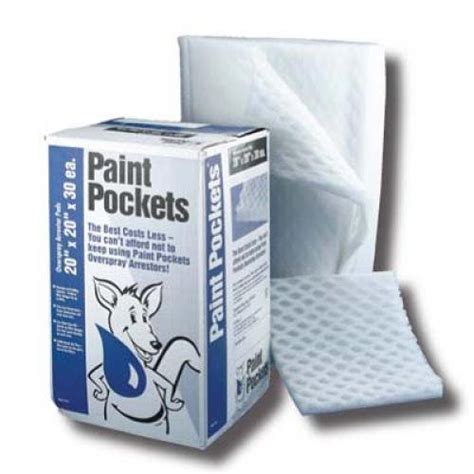

Paint Pockets® is the best performing, single-stage overspray arrestor on the market. Paint Pockets® excels in arresting both liquid and powder coating overspray generated in industrial, automotive, and aerospace applications.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $237.44 through $665.98

Select options This product has multiple variants. The options may be chosen on the product page -

The King Series Premium Media fiber structure and tri-layer design provide an extremely efficient and long lasting media, creating an ideal painting environment with all paint types, including waterborne.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $273.92 through $1,446.27

Select options This product has multiple variants. The options may be chosen on the product page -

GFS 22G Fiberglass Filters are made from continuous filament glass fibers with an open weave pattern.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $169.00 through $969.00

Select options This product has multiple variants. The options may be chosen on the product page -

CPA media is a multi-layer, graduated density polyester designed for high-performance.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $165.00 through $729.00

Select options This product has multiple variants. The options may be chosen on the product page -

A multi-layered, progressively dense polyester, CPA Gold media is suitable as the 1st stage in an aerospace exhaust system.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $330.00 through $699.00

Select options This product has multiple variants. The options may be chosen on the product page -

32G Poly-Backed Fiberglass Paint Arrestors are a heavy-duty, two-stage filter designed for demanding applications requiring exceptional performance.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $538.48 through $1,003.10

Select options This product has multiple variants. The options may be chosen on the product page -

A popular overspray arrestor, GFS 15G fiberglass filters are designed to provide longevity, efficiency and economy for most spray booth applications.

FREE Shipping – Best Way Ground (Continental USA)

Price range: $140.00 through $1,019.00

Select options This product has multiple variants. The options may be chosen on the product page